Contact

Casting

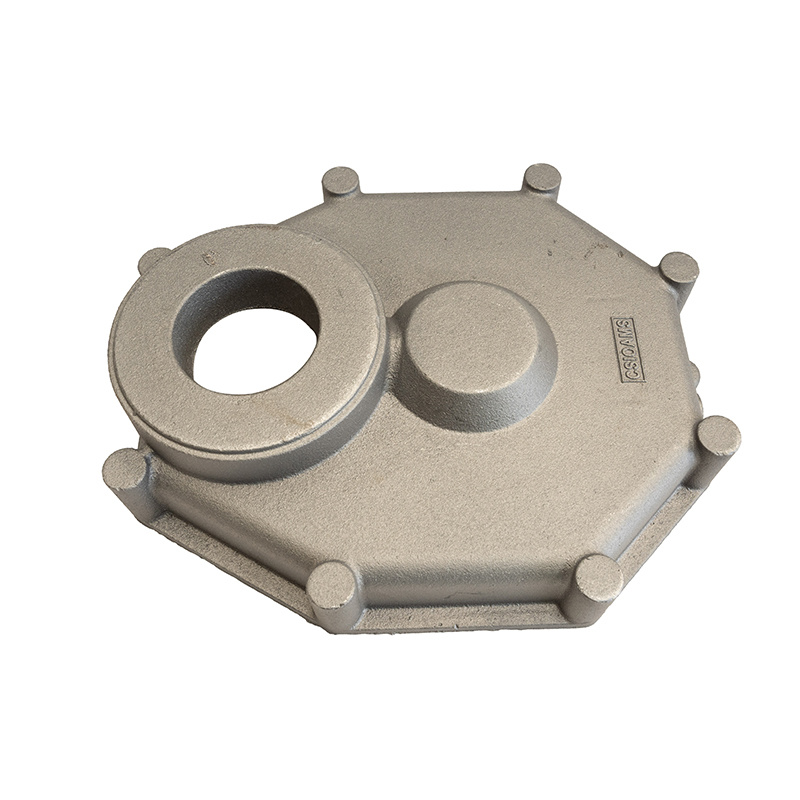

- Commodity name: Casting

- Product Description

-

Transmission equipment castings are indispensable basic components in transmission equipment, they are manufactured by casting process, with specific shape, size and performance to meet the working needs of transmission equipment. The following is a detailed introduction to transmission equipment castings:

Transmission equipment castings refer to various metal forming objects used in transmission equipment, which are obtained through the casting process. According to the different metal materials used, transmission equipment castings can be divided into steel casting, cast iron, cast copper, cast aluminum and so on. According to the specific needs of transmission equipment, transmission equipment castings can be further subdivided into gear castings, bearing castings, shaft castings, shell castings and other types.

Function and effect

Gear castings: As the core part of the transmission equipment, gear castings can accurately transfer power and achieve speed reduction. They require a high degree of precision and strength to ensure smooth and reliable transmission.

Bearing seat castings: The base used to support and hold bearings, bearing important loads and moments. Bearing seat castings need to have sufficient rigidity and stability to ensure the normal operation of bearings.

Shaft casting: The drive shaft in the transmission equipment, which carries various loads and torques, and transmits power. Shaft castings need to have good mechanical properties and wear resistance to ensure the reliability and stability of the transmission.

Shell castings: As a protective frame for transmission equipment, shell castings need to provide sufficient mechanical strength and rigidity to withstand various loads and shocks, and to protect the parts inside the equipment from damage.Manufacturing process and quality control

The manufacturing process of transmission equipment castings mainly includes mold design, melting metal, casting, cooling and curing, sand cleaning and post-treatment steps. In the manufacturing process, it is necessary to strictly control the casting process parameters, such as pouring temperature, cooling speed, etc., to ensure the quality and performance of the casting. At the same time, it is also necessary to carry out the necessary inspection and testing, such as appearance inspection, size measurement, mechanical property testing, etc., to ensure that the casting meets the design requirements.

Application areas and importance

Transmission equipment castings are widely used in various mechanical equipment, such as automobiles, ships, aerospace, engineering machinery and other fields. Their quality and performance directly affect the working effect and service life of the transmission equipment. Therefore, in the manufacturing process of transmission equipment, it is very important to choose the right casting material, optimize the casting process parameters, and strengthen the quality control.

Key words:

Related Products